Jörg Hellmich1, Volker Lenzner2

Using the CANopen-Lift standard, system data from the control system and components are available on the bus in real time. With the flexyPage system of ELFIN the data are edited and visualised in a flexible manner. On the occasion of the Interlift 2015 the LiftEquip company presented the energy recovery topic by way of the energy data example.

In the past the elevator energy efficiency topic has already been discussed on numerous occasions also in connection with the energy recovery and several papers have been presented on different conferences.

Since the energy saving ordinance (EnEV) fails to name the elevator, no concrete measures are defined which need to be taken and met. But even without these specific EnEv requirements there have been various approaches in the past to reduce the energy demand of elevator systems.

The directive VDI 4707 in parts 1 and 2 first of all considered on a national level the energy topic for elevators and elevator components which was later also described on an international scale in the ISO 25745-1 standard which is largely based on the principles of the VDI directive.

For the operation of the elevator this paper takes a look at the ‚riding’ and ’standby’ operating conditions and uses defined utilization categories to take into account the rides needed to determine the overall efficiency of the system. In the ’riding’ operating mode the converter is the component which by using the energy recovery instrument can make a major contribution to the elevator’s energy efficiency.

In the past energy recovery systems have been used primarily in high-frequency systems and plants with high frequency converter outputs to reduce the generation of heat of the regeneration resistors which is critical in many applications and which sometimes can Jörg Hellmich1), Volker Lenzner2) only be controlled using additional airconditioning systems in the machine room.

In standard applications and in elevator systems that are not very frequented, an energy recovery system has often been excluded since most of the energy (70 to 80%) of these systems is needed during standby. It made more sense for these particular elevator systems only to take measures which reduce the energy consumption.

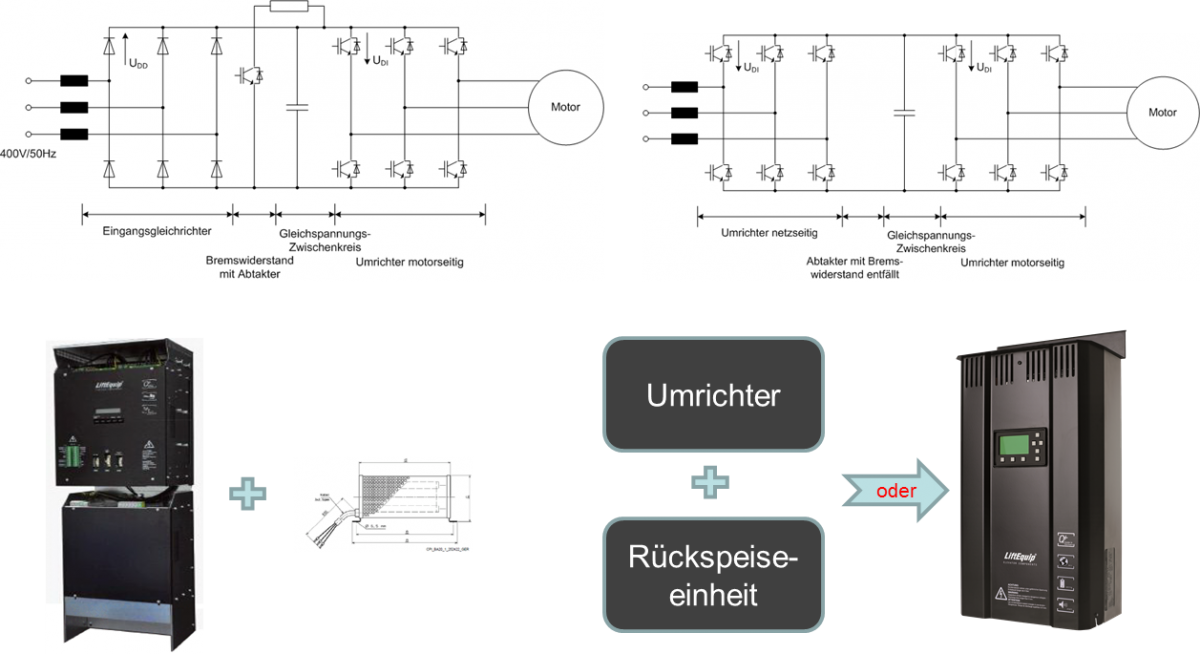

Many frequency converter systems that are available on the market and allow energy to be recovered consist of two separate components; the actual frequency converter and the separate energy recovery unit. In this constellation the extra costs must be identified and the standby energy demand of the energy recovery unit must be examined. Often the investment for systems with a low performance and utilization is economically unwise.

With the converter of the MFR series LiftEquip offers a system with an integrated energy recovery unit which recovers energy from the first ride onward at no extra cost and as such contributes to the economic efficiency of the elevator system.

In discussions held with planners, operators and elevator manufacturers the following questions frequently crop up:

- How much energy is recovered?

- When is energy recovery worthwhile?

- What does the energy recovery cost?

- What happens to the recovered energy?

Fig. 1: Converter operation with and without energy recovery

It is obvious from explanations earlier in this paper that there is no collective answer to these questions since a lot of individual parameters need to be taken into account.

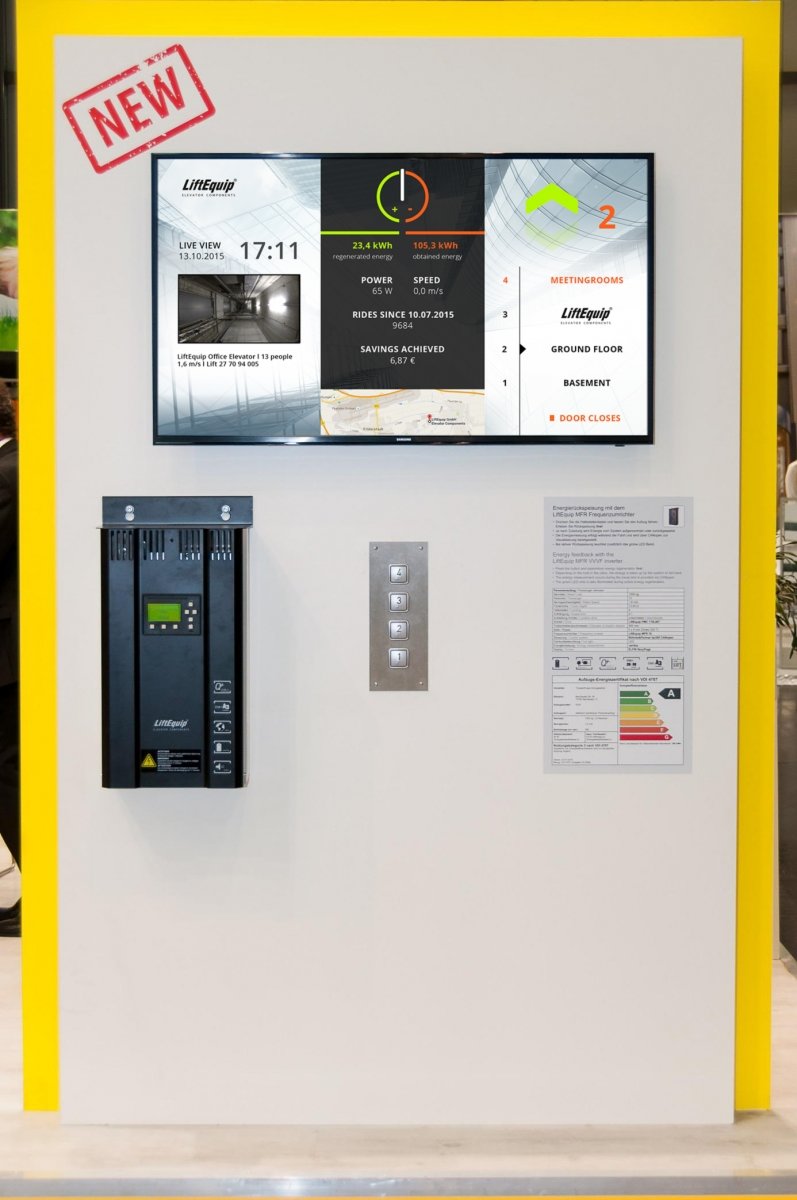

Prior the Interlift exhibition, LiftEquip, Böhnke + Partner and ELFIN jointly thought about ways to visualise the ”energy recovery” topic in a simple and informative manner.

For this purpose an elevator in one of LiftEquip’s buildings was modified. In the elevator with CANopen-Lift capabilities a converter of the MFR series is controlled by a bp308 control system. The following table shows the system parameters of the system used.

For measuring the energy demand the elevator was equipped with an energy measuring system of Janitza and the measured data were made available on the CANopen bus. Using the ELFIN flexyPage system the measured data were read from the bus and transferred together with the current position values, the ride counter and the live picture of a video camera via a safe VPN connection to the exhibition stand where they were visualized on a big screen. With the aid of this system the exhibition visitors could enter car calls and directly follow the ride movements of the elevator and the flow of energy caused by the operation.

Fig. 3: Presentation of the current system data and measurements

Apart from the system parameters and the system’s position, the screen also displayed the system’s calls, the current floor position and the ride direction. A new pointer instrument was developed for displaying the performance which indicates whether the elevator is drawing energy from the power system or is working in a regenerative mode and supplies energy back into the power system. In conjunction with the two measured data of the total energy drawn from and supplied back to power system and the direct display of the energy costs saved, the observer got an idea of the efficiency of the energy recovery system.

In order to be able to display the mode of operation of the energy recovery system in connection with the load condition, it is planned to equip the elevator with new load measuring sensors which can make available the current load on the CAN bus.

Since the MFR converter of LiftEquip is offered at no extra cost compared to the MFC converter with the same performance, every kilowatt hour supplied back to the power system is a direct saving.

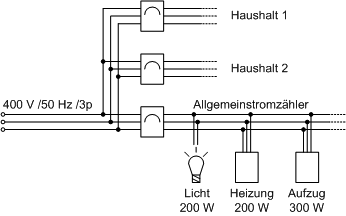

Since elevators are not subject to the Renewable Energy Act a refund for energy not consumed in the building and supplied back to the power supply network is not possible. But since every building has a regular basic energy demand, the energy as a rule is consumed in the building. So energy is available to the building which does not have to be procured from an external source.

Fig. 4: Energy drawn from the power supply in the building

During the four days of the Interlift 2015 exhibition a total of 1982 rides were made with the elevator, 27.5 kWh being drawn from the power supply for the traction operation and 8.1 kWh being produced in the regenerative mode and supplied back to the building’s power supply network. With a charge of 0.29 € per kWh this corresponds to savings of 2.35 € for the four days and annual savings of 214.40 €. Energy recovery not only results in a better energy classification of the elevator system but also directly yields an economic benefit. Depending on the degree of utilization elevators provide different savings which may sometimes prove to be quite small. But in view of the total number of elevators (in Germany approx. 700,000 systems) the saving potential cannot be ignored. Whenever this is economically possible, one should therefore always include the energy recovery option when installing new elevator systems. And even when systems are only modernized and the drive system is replaced, energy recovery is an option to contribute to a reduction of the CO2 level and to the protection of the overall environment.

Summary

The publication of VDI 4707 turned the spotlight on the energy demand of elevators. The project described in this paper clearly shows how intelligent energy recovery applications allow energy to be saved from the first ride onward. Other savings are achieved by networking the components via the open standard CANopen-Lift allowing energetically optimized ride curves and a distinct reduction of the energy demand in standby mode. CANopenLift is also the basis for the measurement, visualization and transmission of energy values with the flexyPage system. In conjunction with other sensor data, the networking option provides additional possibilities for an energetic optimization of components and systems in special operating conditions.

|

Table: System of the measured elevator system |

|

|---|---|

|

Passenger elevator |

|

|

Nominal Load |

1.000 kg |

|

Passenger |

13 |

|

Nominal Speed |

1,6 m/s |

|

Travel height |

19,93 m |

|

Landing |

4 |

|

Suspension |

2:1 |

|

Local drive |

down/beside |

|

Drive |

LiftEquip PMC 170L007 |

|

Diameter of traction sheave |

400 mm |

|

Ropes |

5 x 8 mm (Drako 250 T) |

|

Frequency system |

LiftEquip MFR 18 |

|

Car light |

Böhnke + Partner bp308 CANopen |

|

Car light |

LED |

|

Energy measurement |

Janitza |

|

Display |

ELFIN flexyPage |

1) ELFIN

2) LiftEquip

lift report year's issue 42 (2016) magazine 1