Optical Bonding significantly increases image quality and readability of displays. As a special technology to avoid reflections optical bonding creates a better contrast. But why is that the case and how does it work? We compiled some information in the following paragraphs.

Extrinsic Contrast

To make a display visible in daylight the background lighting will be increased in most cases. As a result, both black and white pixels appear brighter. Displays with an especially strong background lighting usually possess a lower contrast. Another factor lowering the contrast of the display is the incidental light that is reflected by the display. Here we are talking about extrinsic contrast, which is to be seperated from the contrast in dark environments mentioned in a manual. The extrinsic contrast is calculated considering the ambient lighting. To reduce it, the reflections of the display and the glass have to be reduced.

Functionality of Optical Bonding

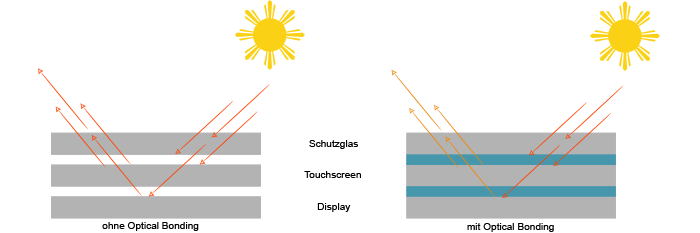

The strongest reflections occur at the spaces between glass and touchscreen, as well as between touchscreen and display, which are usually filled with air. Optical Bonding eliminates the air completely and thus eliminates the main reason for bad contrast in ambient light as well. This increases contrast significantly.

As an additional benefit, optical bonding increases the resilience of the display. This is because the whole construction is less suspectible to damage by vandalism and vibrations or stress as a result of differences in temperature.

Advantages of Optical Bonding at a glance

Better readability without higher energy demand

Glueing together the glass and the display, or vaccuumizing the space in between, the light refraction is reduced significantly. This increases contrast. The intensity of the background lighting can be reduced. The energy demand decreases. This decreases costs as well and helps our environment.

No condensation or fog production

No contamination

It is also impossible for dust particles and dirt to enter in between the display and the glass.

High resistance to vibrations and shock

A bonded display is more stable and resilient against mechanical strain. The special glue used in Wet Bonding works against resonance phenomena and transmits pressure from the front towards the sides.

Improved heat dissipation (up to factor 8)

By closing the insulating air gap the heat of the display can be dissipated more easily through the front glass. This increases performance as well as longevity of the display.

Process

In Optical Bonding there is a distinction between Vacuum Bonding and Wet Bonding, which have different effectiveness depending on the size of the display. In Vacuum Bonding the usually air-filled gap is vacuumized, in Wet Bonding a type of glue is inserted into the gaps. The process takes place in a cleanroom, to prevent the inclusion of dust and other contaminants. In Wet Bonding, however, an inclusion of air bubbles can never be ruled out completely. This increases production costs.